Fuel Sender

Removing the fuel sender from the MK2 CRX.

Important - Read this First!

Before removing the sender make sure the level in

tank is as low as possible, and use common sense when

working with an open fuel tank. Keep the doors open to

prevent a build up of vapour in the car, which can

easily be ignited with a spark. If you are working in a

garage, make sure there is plenty of ventilation, and

those around you know there is an open fuel tank.

Naturally, if you intend to have the sender unit out

for any length of time, you should drain the tank

completely.

It's also worth mentioning that to gain access to the

fuel pump you must remove the tank from the car, as it

is offset to one side under the body.

Removal

The car shown here is a 1991 CRX, however removal is

similar for a wide range of Honda vehicles. There is no

need to remove the tank from the car to get to the

sender as there is an access hole under the back seat.

|

Remove the 10mm retaining bolt for the seat, pass the

seat belt buckles through the openings and then flip up

the seat from the rear to a vertical position and unhook

at the front. It should just lift out. |

|

Remove the 10mm retaining bolt for the seat, pass the

seat belt buckles through the openings and then flip up

the seat from the rear to a vertical position and unhook

at the front. It should just lift out.

With the seat removed, you can see the access hatch.

Unplug the connector and undo the screws to remove the

cover. |

|

You can now unplug the connector to the sender unit

itself, the other wires running off along the top of the

tank are for the fuel pump. |

|

With the connector to the sender unplugged, wash round

the top of the tank with a strong detergent and brush to

remove all the dust as you don't want it to fall into

the tank, it also allows you to get a clearer view of

the retaining ring. Was away the detergent with water -

it will run out off the top of the tank, so it's best to

do this job outside. Do not worry about getting any

water inside the tank, as the sender unit is well sealed

although naturally you should dry off any excess water. |

|

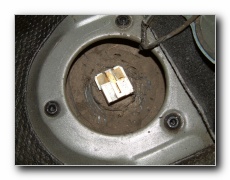

With everything clean you can see the retaining ring.

Honda have a special tool available at cost to remove

this ring, but you can make do with a large screwdriver

or preferably steel rod to gently tap the ring round.

You may be able to loosen it with a pair of large long

nosed pliers, but it usually need some persuasion the

first time. Be careful not to bend or twist the

retaining ring, it does not need much force to remove

it. You must rotate it anticlockwise until the lugs line

up the bracket on the tank, allowing you to lift out the

ring. The ring has a cam on it to press the sender unit

and seal down hard to the tank - once this has been

passed it should spin round without too much trouble,

depending on how much dust & grit is still stuck in the

ring & bracket!

|

|

When the ring is free,

carefully lift out the sender and be careful not

to bend the float arm. It has a rubber seal

which may fall down when the sender is lifted

out, so make sure to take note of which way

round it fits. |

|

It's also worthwhile to clean

up the ring and top of the sender unit now they

are out. |

Refitting

|

To refit the sender, make sure the rubber seal is

correctly fitted on the sender unit. |

|

Now place the sender unit into the tank, making sure it

is correctly located - there is a tab on the top that

lines up with a groove on the ring's bracket. |

|

Now place the cleaned up ring into the bracket and let

it drop down, you will have to press down on the sender

to compress the seal while doing this. Note that the

sender on the B16 engined cars is slightly different to

the earlier D series models, as it is spring

loaded to press down on the bottom of the tank,

so requires a little more force. |

|

I managed to tighten the ring with a

some long nosed pliers. Tighten the ring until it

reaches the end stop, do not force it and be careful not

to distort the ring or the bracket. |

|

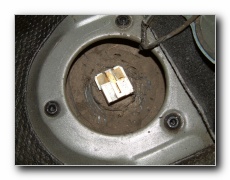

The ring correctly installed. |

|

You can now install the connector again, notice that i

have also cleaned up the rubber cover to keep everything

tidy. Screw the access hatch back down, plug in the

connector to the main loom, and that's it. |